Electricity

Moving charges generate magnetic fields (so current always has a magnetic field), and a change in magnetic field, with a loop of wire around it, has a changing current in that loop. (A current is moving positive-charge, and voltage is the energy needed to move a charge forward to make a current.). A change in magnetic field produces an electric field (Faraday’s law), while a changing electric field produces a magnetic field (Maxwell–Ampère law). Together, this symmetry allows electromagnetic waves to exist.

Electrons are not produced by a change in magnetic field. A change in magnetic field does not create electricity, but only energy to move the electrons in a wire, from mechanical energy.

Current is the flow of charge in a particular direction. If they were not in a particular direction, they are safe to touch. An example is keys, the electrons in keys are obviously moving, but not in a particular direction. Electrons move in the direction opposite of the electric field, whereas protons move in the direction of the electric field. Both electrons and protons travel from high voltage to low voltage, so in a wire, 1 end of the wire has a higher voltage (synonymous with potential and pressure) than the other. If both ends of the wire had the same voltage, then the electricity would not be moving in a direction. When the electrons hit the resistor, heat is produced.

Just like mass tell us how much an object or particle affects the gravitational field, charge tells us how much an object or particle affects the electromagnetic field.

We need both electric and magnetic field for energy to flow. Electric and magnetic fields are perpendicular. Energy cannot flow in the same direction as charge, because they're perpendicular. Moving charge moves in the direction of electric field. The flow of charge is what transfers energy, not the individual movement of electrons. Current is the mechanism that allows energy to be transferred through electric fields. We need both electric and magnetic field, for energy to flow.

E = vector for electric field, B = vector for magnetic field, and S (Poynting vector) is for the direction of energy transfer.

Magnetic fields are measured in gauss. The strength of the Earth’s magnetic field is about .57 gauss. 10,000 gauss is a tesla.

Measuring electricity in kilowatts rather than kiloamps or kilovolts.

While amps are the electric current, we don’t actually use the electrons, only the energy of the electrons. Where does the energy of the electron come from? From mechanical energy. Can an electron lose all of its energy? Yes, when it is not moving. And the electrical energy is converted to heat in the resistor.

1 Joule is energy dissipated as heat when an electric current if 1 Amp passes through a resistance of 1 Ohm in 1 second.

What about “proton electricity?”

Imagine electricity, instead of composing of electrons, were composed of protons. Protons are more massive than electrons and are thus harder to move in a wire. It is harder to isolate free protons, since they are found primarily in the nucleus of atoms (and not in the electron cloud).

AC and DC electricity (alternating and direct).

To make AC electricity, take a loop of wire, put big magnetic field through it, and spin it (this is how power plants work). Transformers only work for AC. DC electricity is a specific type of AC electricity, DC is AC with a frequency of 0.

So a moving electrical current creates a magnetic field. Is it possible to distinguish a magnetic field that originated from AC electricity and DC electricity? Yes, because an AC flow creates an alternating magnetic field that in turn induces an alternating voltage in a conductor, such as a wire or a coil, which can be measured. (This is how transformer works.). A DC flow just creates a steady magnetic field, like a bar magnet.

AC works great for large scale long-distance electricity, but not so great on the small scale. That’s where DC is better and cheaper.

When batteries are used as a DC power source in a DC circuit, there is no reactance. Reactance is only something you have to worry about in AC circuits.

AC and DC electricity, and emitting radio waves.

A steady DC electricity does not emit radio waves, but a change in any current does. So AC electricity always emits radio waves. An abrupt change in DC electricity will cause the frequency of the wave to spread all over the spectrum and can be noticed on nearby receivers.

The 1st to convert.

AC to DC (rectification).

The 1st to convert AC electricity to DC was done by rotary (synchronous) converters in the late 1800s. These machines were a motor and generator. But the mercury-arc rectifier was invented by Peter Cooper Hewitt in 1902, and these were 1 of the 1st efficient devices for converting AC to DC in high-power applications.

DC to AC (inversion).

Before solid-state electronics, things like car radios used mechanical inverters, or mechanical circuits plus transformers. But a more modern electronic inverter, was the Royer oscillator invented in 1954 by Richard Bright and George Royer.

-

Romex and circuit breakers.

Romex is a brand name for a type of electrical cable commonly used in residential wiring in the U.S. It typically consists of 2 or more insulated conductors (wires) housed within a non-metallic sheath. Romex cables are commonly used for supplying power to outlets, switches, and other electrical devices in homes. White Romex cable is 14-gauge wire, rated for a 15-amp circuit, while yellow Romex cable is 12-gauge wire, rated for a 20-amp circuit. They have to be paired with the proper breaker. You can put the larger wire on the smaller breaker, and that's not a big deal, but you don't want to put the 14-gauge 15 amp wire on the 20-amp breaker, which can cause a fire. For wiring to an outlet from the breaker, the neutral wire goes to the silver screws, the ground wire (copper) goes to the ground screw, and the hot wire (black) connects to the copper screws. The outlet that has the T-shape hole (receptacle or socket) is the side for the neutral wire.

History.

The unification of electricity and magnetism was first demonstrated by the experiments of Hans Christian Ørsted and shortly thereafter by André-Marie Ampère and Michael Faraday in the early 1800s. The work of James Clerk Maxwell established the geometric relationship between electric and magnetic waves that co-propagate orthogonally, and also established that these electromagnetic waves should be indistinguishable from light. Hertz's experiments established the connection between these co-propagating waves and light, specifically in the radio band, but radio is not a different phenomenon than light (as shown by Oliver Lodge among many others), and Hertz's work was expanded on by the work of Jagadish Chandra Bose. Joseph Larmor, for whom is named the Larmor principle, established that accelerating electric charges always emits electromagnetic radiation, and established the math for which it occurs.

What is safer, 120 V in US, or 220 V in UK?

There's 2 factors to consider: fire safety, and electrocution.

Heat is generated by a conductor at the rate of I2R:

The rate of heat generation in a resistance is given by the product of the current through it and the voltage between its ends. But the voltage drop across a poor connection in domestic wiring is not equal to the supply voltage, since the connection is in series with some domestic appliance such as an oven. Unless the connection is very bad indeed, its resistance will be far lower than that of the appliance. In that case the current in the circuit is approximately the power rating of the appliance divided by the supply voltage (so double the current for half the supply voltage). The voltage dropped by the poor connection is the current times its resistance (so doubled by doubling the current). That means for an appliance of given power, and a connection of given resistance, the heating at the connection is 1/4th by doubling the supply voltage, consequently decreasing the fire risk.

This is an over-estimate, as we have neglected the fact that the poor connection will reduce the current slightly (though it is easy to correct for that).

For a voltage source that is twice as high, the heat generated in the wiring drops (watts, P) to 1/4th:

The heat produced in a conductor is the square of the current multiplied by the resistance of the conductor. If an appliance draws a given power P, and we consider 1st 1 supply voltage, and then consider doubling that supply voltage but still supplying power P to the appliance; doubling the voltage will cause the current in the wiring to halve. The heat produced with half the current will be only 1/4th of the heat produced in the 1st case, simply because joule heating is directly proportional to the square of the current providing the resistance is unchanged. So the risk of fire caused by joule heating in the wiring decreases dramatically as supply voltage is increased to an appliance drawing a given power P.

Since electrical resistance is temperature-dependent, the voltage-current relationship is significantly non-linear over a wide enough temperature range.

Therefore resistance is quadrupled. R = V/I. R gets stronger as V gets bigger and I gets smaller.

Higher voltage increases considerably fire safety: That is why Europe moved from 110 V to 240 V at the beginning of the 20th century: this way they had not to replace miles and miles of wire no more able to manage the rapidly growing loads. The point is that doubling the voltage you can double the impedance of your appliance to do the same work, thus halving the necessary current. By halving the current you divide by 4 the resistive heating of the conductors.

So the reasoning that by doubling the voltage you also double the current if the circuit doesn't change is true but irrelevant as the circuit must and will change: a toaster is part of the circuit, and a toaster drawing 800 W by 110 V must more than double its impedance to draw 800 W by 240 V, thus more than halving the necessary current. Generally speaking, by doubling the voltage transmission losses are reduced by a factor of 4, that is why very long overhead power lines are operated with tensions up to 1 MV.

Electrocution.

The thing that protects us all from electrocution is the insulation surrounding all live conductors; the higher the voltage, the greater the amount of insulation that is required, but there is always a risk that the insulation surrounding an appliance will be damaged, allowing a person to come in contact with a live conductor. Keeping the voltage low is an alternative to using increasing amounts of insulation so it can be argued that people who live in a country where the domestic supply voltage is 110 V are safer with respect to electrocution than those who live in a country where 220 V is supplied.

The lower domestic supply voltage in the U.S., and consequent higher current, necessitates thicker wires. Thick wire uses a lot of copper, which is expensive. This motivated the use of aluminum wiring in domestic premises in the U.S. in the 1960s and '70s. Achieving and maintaining a good electrical connection to aluminum can be problematic, and poor connections a fire hazard (especially those carrying high currents). In this way the lower voltage did, somewhat indirectly, lead to a fire risk.

Electrochemistry:

Alkaline battery: Zinc in negative end (anode), manganese dioxide in positive end (cathode), separated a thin insulator of potassium hydroxide and water.

Older battery: the acidic ammonium chloride is used instead of KOH, but this older batter had increased Zn corrosion.

Car battery: Lead in anode side, lead dioxide as cathode, surrounded by sulfuric acid solution (in which the electrodes are immersed in).

Lithium ion battery: graphite in anode side, nickel, cobalt, and lithium for metal oxide in cathode side. The power source sucks electrons from lithium into the graphite, while the lithium (now as ions) are attracted to, and flow through the electrolyte to get into the graphite. Once all the lithium gets to the graphite, the battery is fully charged. A fire or explosion will happen if the liquid electrolyte dries up (from excess heat), causing a short circuit between the anode and cathode.

Lithium ion batteries were invented in 1991 by Sony. They are almost 6x more expensive than a lead acid battery, and 3x more than a nickel metal hydride battery, due to the presence of nickel and cobalt, in the metal oxide compound. As of 2020, lithium ion batteries have the greatest energy density of other batteries (240 Watt hours/kg, NiMH at 90 Watt hours/kg) but still inferior to that of gasoline (12,200 Watt h/kg). NiMH batteries were discontinued in 2000.

Note that for lithium ion batteries, the metal oxide used varies depending on the type of Li ion battery. As stated earlier, nickel and cobalt is used for the traditional batteries, nickel and magnesium is used for a Tesla battery, and cobalt oxide is used for a smartphone battery.

Lithium has the lowest electrochemical reduction potential and density of any metal, making it an exceptionally desirable anode material for batteries and a powerful chemical reductant. However, the reducing nature which makes Li so useful brings challenges: it is thermodynamically unstable in practical liquid electrolytes, driving the formation of a nanoscale passivation film called the solid electrolyte interphase (SEI). The SEI mediates transport and reactivity at Li surfaces, and its composition and structure arise spontaneously from the chemistry of the electrolyte.

A standard Tesla cell has a voltage of between 3 and 4.2 volts. They are connected in series, and in a parallel fashion to form a module. 16 modules are connected in series to form a battery pack in a Tesla car.

In 2019, Stanford lab developed a method for Li-metal batteries to retain 85% power after 160 cycles, which is a major improvement of a traditional 30% power.

In 2000, Li-ion batteries were >$2,000/kWh, and in 2020, were $100/kWh.

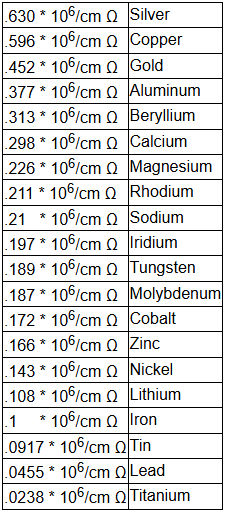

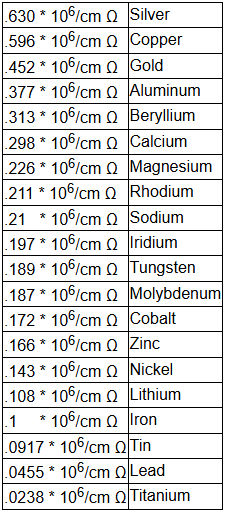

Conductivity table, in inverse cm-ohms.

Electric vehicle batteries.

The lifespan of an EV battery depends on a number of factors. While battery life can vary, EV manufacturers are required to issue a warranty for at least 8 years or 10,000 miles. However, some manufacturers offer longer warranties. Kia offers a battery pack warranty for 10 years or 100,000 miles, and Hyundai provides warranty coverage on EV batteries for the vehicles entire lifetime. Battery warranties vary not only by time but also the nature of the coverage. Some automakers will only replace the battery if it completely dies, while other brands like BMW, Tesla, and Volkswagen, will cover a battery if battery capacity falls below a certain percentage.

An electric vehicle battery is expected to last 10-20 years depending on maintenance and care.

As battery technology continues to evolve, companies are creating larger batteries with increased range. For example, the 1st generation Nissan LEAF had a maximum range of 84 miles, while the newest LEAF (June 2023) has a maximum range of 212 miles. The advanced technology of these larger batteries also reduces their degradation. Even as they degrade, they will still maintain a long battery range. Moreover, a Tesla Model S only loses an estimated 5% of battery capacity over its 1st 50,000 miles.

For maintaining an EV battery's life, there's 3 things you can do. They are avoid extreme temperature, avoid charging your vehicle above 80% or below 20%, and do slow charging. DC fast charging stations can bring your battery level up to 80% in as little as 30 minutes, but With this convenience comes a strain on your EV battery.

EV batteries in June 2023 and Dec. 2023.

Toyota has a new CEO in April 2023, and is making some big changes in the industry. Currently, the longest EV battery life is Lucid's air grand touring (sedan) at 516 miles / charge, however, it is a luxury vehicle starting at $139,000. Toyota's 1st hybrid Prius was 70 miles / gallon in 1999. Toyota's current EV, the BZ4X, ranges around 318 miles / charge. EV batteries also make up about 30-40% of the total cost of the EV.

Lucid's EV, the Air luxury sedan, which can accelerate from 0 to 6 mph in <2 seconds, and costing more than $250,000, can travel up to 527 miles on a single charge, Dec. 2023.

12/29/2023: Nio, a Chinese electric car firm and Tesla rival, has developed a battery with a 1,000 km range. The CEO tested it, by driving 14 hours between 2 cities, at 1,044 km with 3% battery (Shanghai to Xiamen), on Dec. 17. Nio is planning to begin mass-producing this 150 kWh batteries in April 2024. However, it will cost around $42,100.

The Tesla Model 3 has a fuel efficiency rating of 134 miles per gallon equivalent (MPGe).

By early 2025, the Tesla Model 3 range is 363 miles, 0-60 mph in 4.9 seconds, and price of $34,990. The fast charging rate is up to 200 miles in ~15 minutes at 250 kW.

Energy density per battery cell:

Nickel manganese cobalt 275 Wh/kg vehicle range 450 km = 280 miles

Lithium iron phosphate 180 Wh/kg 300 km = 186 miles

Sodium ion 160 Wh/kg 230 km = 143 miles

Components of EV batteries.

Within EV batteries are 5 key technical elements: the anode, cathode, separator, electrolyte, and lithium ions. The most commonly used varieties of lithium ions are lithium cobalt oxide (LCO), lithium manganese oxide (LMO), lithium iron phosphate (LFP), lithium nickel cobalt aluminum oxide (NCA) and lithium nickel manganese cobalt oxide (NMC). A typical EV battery (NMC532) contains roughly 35 kilos (77 lbs) of nickel, 20 kilos (44 lbs) of manganese, 14 kilos (30 lbs) of cobalt, and 8 kilos (17 lbs) of lithium carbonate. There are a wide range of lithium batteries on the market that combine different metals and lithium, such as manganese or iron.

-Cobalt is the most expensive metal used in batteries but is also the heaviest. Cobalt has a very high electrochemical potential and is a soft metal resistant to heat and corrosion.

-Lithium is the lightest metal and has the greatest electrochemical potential. It can store more energy than other metals. However, lithium iron phosphate is also the most expensive metal used in batteries, and its abundance is limited.

-Nickel is cheaper and less reactive than lithium, with a slightly lower electrochemical potential.

-There are 2 main types of copper used in EV batteries:

Pure copper: typically used in electric vehicles with high power output, such as Tesla’s Model S and X.

Copper alloy: typically used in electric vehicles with lower power output, such as the BMW i3 and the Nissan Leaf.

The electrodes in an EV battery are where the actual chemical reaction occurs. They’re made of lithium, cobalt, nickel, or manganese.

EV production relies on imported minerals, primarily from Canada, China, Chile, Gabon, Norway, and Argentina.

Update on EV batteries dated Nov. 2, 2023:

It has not been clear why some batteries go into thermal runaway, even when an EV is parked. Now, by using an imaging technique called “operando X-ray microtomography,” scientists at Lawrence Berkeley National Laboratory (Berkeley Lab) and UC Berkeley have shown that the presence of large local currents inside batteries at rest after fast charging could be 1 of the causes behind thermal runaway. The team is also the first to measure ionic currents at the particle level inside the battery electrode.

Measuring a battery’s internal currents:

In a lithium-ion battery, the anode component of the electrode is mostly made of graphite. When a healthy battery is charged slowly, lithium ions weave themselves between the layers of graphite sheets in the electrode. In contrast, when the battery is charged rapidly, the lithium ions have a tendency to deposit on the surface of the graphite particles in the form of lithium metal.

Experiments led by first author Alec S. Ho (who recently got a Ph.D there) at the Advanced Light Source (ALS) show that when graphite is “fully lithiated” or fully charged, it expands a tiny bit, about a 10% change in volume – and that current in the battery at the particle level could be determined by tracking the local lithiation in the electrode. A conventional voltmeter would tell you that when a battery is turned off, and disconnected from both the charging station and the electric motor, the overall current in the battery is zero. But in the new study, the research team found that after charging the battery in 10 minutes, the local currents in a battery at rest (or currents inside the battery at

the particle level) were surprisingly large. Parkinson’s 3D microtomography instrument at the ALS enabled the researchers to pinpoint which particles inside the battery were the “outliers” generating alarming current densities as high as 25 milliamps per cm squared. In comparison, the current density required to charge the battery in 10 minutes was 18 milliamps per cm squared.

Photovoltaics.

The photovoltaic effect is the generation of voltage and electric current in a material upon exposure to light. This was 1st demonstrated by Edmond Becquerel in 1839 in France. Photovoltaics is the conversion of light into electricity using semiconducting materials that exhibit the photovoltaic effect.

Efficient photovoltaics require capturing and converting solar energy across a broad range of energy. Losses due to thermalization and sub-bandgap place, however, significant boundaries on the performance of solar cells. For conventional single-junction cells, the theoretical maximum power conversion efficiency is capped at 33%, a constraint known as the detailed balance limit.

For high-energy photons that exceed the semiconductor’s bandgap energy, singlet fission (SF) is a downconversion pathway to mitigate thermalization losses. A process in organic materials, singlet fission is where a singlet excited state is split into 2 independent triplet states, effectively doubling the number of charge carriers. Pentacenes stand out among acenes due to their exergonic nature of singlet fission. Numerous molecular pentacene dimers have been synthesized to elucidate the relationship between structure and enhancing singlet fission efficiency. A broader light-harvesting range of singlet fission materials is realized by covalently attaching complementary absorbing energy donors to set up energy donor-acceptor conjugates. Förster resonance energy transfer (FRET) is operative in these energy-donor chromophores and extends the effective absorption of singlet fission materials as they efficiently transfer their absorbed excitation energy. FRET efficiency depends not only on parameters like the energy donor-acceptor distance and spectral overlap but also on subtle factors such as the alignment of transition dipoles, which significantly affect the energy transfer dynamics and efficiency.

Turning to low-energy photons, triplet-triplet annihilation upconversion (TTA-UC) provides a means of light upconversion and, thereby, the reduction of sub-bandgap losses. In TTA-UC, a singlet excited state that is potent enough to generate charge carriers is formed by combining 2 triplet excitons. It is effectively the reverse process of singlet fission. The higher triplet energy of tetracene and an endergonic singlet fission, renders them highly effective for TTA-UC.

Electrical power plants.

Grid connection is a real bottleneck. New generators must complete an interconnection process before starting operation. Interconnection is the single largest barrier to solar development. Interconnection happens early in the project development, before construction. The interconnection queue is a waiting list of proposed power generation and storage projects that seek to connect to the electrical grid. It usually takes several years from entering the queue to beginning operation. The queue is dominated by solar, wind, and natural gas. It is inexpensive to enter the queue. Generators can enter the queue twice a year. About 85% of renewable energy that enters the queue, and 68% for fossil fuels, never begin operation, due to delays, costs, or regulatory barriers. The engineering studies are done by the transmission owners.

In the U.S., the interconnection queues are managed by regional transmission organizations, or regional grid operators, the largest being PJM which is in the Midwest and Mid-Atlantic (affecting ~65 million people). In Chicago for example, ComEd does not control the high-voltage tranmission grid or interconnection process for new power plants, that is done by PJM Interconnection. PJM determines whether a new power plant or energy storage project can connect to the grid that goes across multiple states, and oversees the interconnection queue for new power generators in ComEd's service area. It also operates the wholesale electricity market, where power plants sell electricity. ComEd is a tranmission owner, also known a load-serving entity, to PJM.

The 2nd largest regional grid operator in the U.S. is MISO (Midcontinent Independent System Operator) which also covers the Midwest, as well as southern U.S. and Manitoba, Canada. Others include California ISO, New York ISO, Southwest Power Pool, and ERCOT (Texas).

The largest transmission owner in the U.S. is Pacific Gas & Electric, in terms of transmission assets, and number of customers served, at 16 million, for northern and central California, followed by Soutern California Edison, at 15 million. In terms of transmission lines, they have 18,000 and 12,000, but the largest in terms of transmission lines is American Electric Power, but with multiple grid operators (PJM, MISO, and SPP), consisting of 40,000 miles, but only serving 5.5 million people.

ComEd does not generate electricity, it buys electricity from PJM, where PJM is supplied electricity by companies such as Constellation Energy, Vistra, NRG, Dynegy, and other renewable operators. ComEd is owned by Exelon, but after 2022, Exelon spun off its power generation business Constellation Energy (Constellation and Exelon merged in 2012).

Polarization current.

Polarization current is created when electric dipoles reorient under a time-varying electric field. This happens inside dielectrics. Polarization current is almost always AC, and not DC. (If the electric field is constant, the dipoles align once, and after that nothing changes. Polarization current also cannot be created directly under a magnetic field, as a steady magnetic field does not directly cause dipoles to reorient. However, a time-varying magnetic field creates an electric field, and a time-varying electric field causes dipoles to oscillate, and the oscillating dipole motion is polarization current.

Condensed matter physics.

Persistent current.

In condensed matter physics, persistent current is a steady, never-ending electric current that flows in a closed loop without any applied voltage and without decaying over time, as long as certain quantum conditions are maintained. This is purely a quantum mechanical phenomenon and has no classical analogue. So, a persistent current is dissipationless, driven by quantum phase coherence, and typically observed in small metallic or superconducting loops. Even if you remove the battery or magnetic field that originally induced it, the current keeps flowing. This happens because electrons in a loop must satisfy a quantum phase condition:

∮∇φ⋅dl = 2πn

The electron wavefunction must match up with itself after going around the loop, so the phase must be single-valued. If the loop encloses magnetic flux (Φ), then the allowed electron states shift. The loop ends up with a ground state that carries current, even when no electric field is present. This is similar to particle on a ring with quantized momentum.

2 major types:

-Persistent current in superconductors. This has Cooper pairs form a coherent macroscopic wavefunction, and the phase stiffness prevents dissipation. Currents can last for decades without decay. This is used in MRI magnets and superconducting (flux) qubits.

-Persistent current in non-superconducting metal rings. These are extremely small, in nanoamp to picoamp scale, observed in tiny gold or copper rings, at very low temperatures, rely on phase coherence of electron wavefunctions, and are destroyed easily by scattering and temperature.

What keeps the current rom stopping?

-Quantization, where the momentum of electrons around the loop is quantized, and the ground state can have non-0 angular momentum.

-No or very low scattering, including losing phase coherence, which rarely happens at low temperatures.

Difference between classical current:

Classical current decays due to resistance: I(t) = I0e-tR/L. But persistent currents ignore Ohm's law because they are ground-state currents not created by applied voltage.

Persistent current is also only DC. And while there is an AC Josephson effect (superconductors), which is a voltage applied across a Josephson junction producing an AC supercurrent, this is not persistent current because persistent current requires an applied voltage, the system is out of equilibrium, and the current oscillates with frequency f = 2eV/h.

When was persistent current 1st discovered?

In 1983, Markus Büttiker, Yoseph Imry, and Rolf Landauer predicted that persistent currents should exist even in non-superconducting (normal-metal) mesoscopic rings, when threaded with a magnetic flux. But the 1st experimental evidence for persistent currents in normal metal rings was reported in 1990 by a group at Bell Labs (Laurent Lévy et al.) using SQUID-based magnetometry.

If persistent current exists, then what about persistent voltage?

No, there is no true analogue of persistent voltage. A voltage (electric potential difference) is fundamentally associated with an electric field, which would drive charges to rearrange, and that rearrangement would neutralize the electric field. If you tried to maintain a voltage in a superconducting loop, charges would move until the field cancels. So in all superconductors, a static electric field cannot exist inside a superconductor. If you put a voltage across a superconductor, it produces current that immediately cancels the electric field, so the voltage goes to 0.

-

News.

7/8/2025.

On Tuesday, Lucid got accepted for a new Guinness World Records title for the longest distance ever traveled by an electric vehicle on a single charge. The milestone was achieved over the weekend when the Lucid Air Grand Touring covered 1,205 km (749 miles) without needing to recharge, driving between St. Moritz, Switzerland and Munich, Germany, navigating mountain roads, highways, and secondary routes, surpassing the previous record of 1,045 km, by 160 km.

With an energy efficiency of just 13.5 kWh/100 km, it stands as the market leader in range. The sedan delivers up to 831 PS, reaches speeds up to 270 km per hour (168 mph), and offers a spacious interior designed for 5 passengers.

This marks Lucid’s 2nd major record in collaboration with Umit Sabanci, a London-based entrepreneur renowned for his achievements in electric mobility. In 2024, Sabanci completed a single-charge journey across 9 countries in a Lucid Air.